The difference between silicon calcium board and calcium silicate plate

Time: 2023-02-23 17:48:45

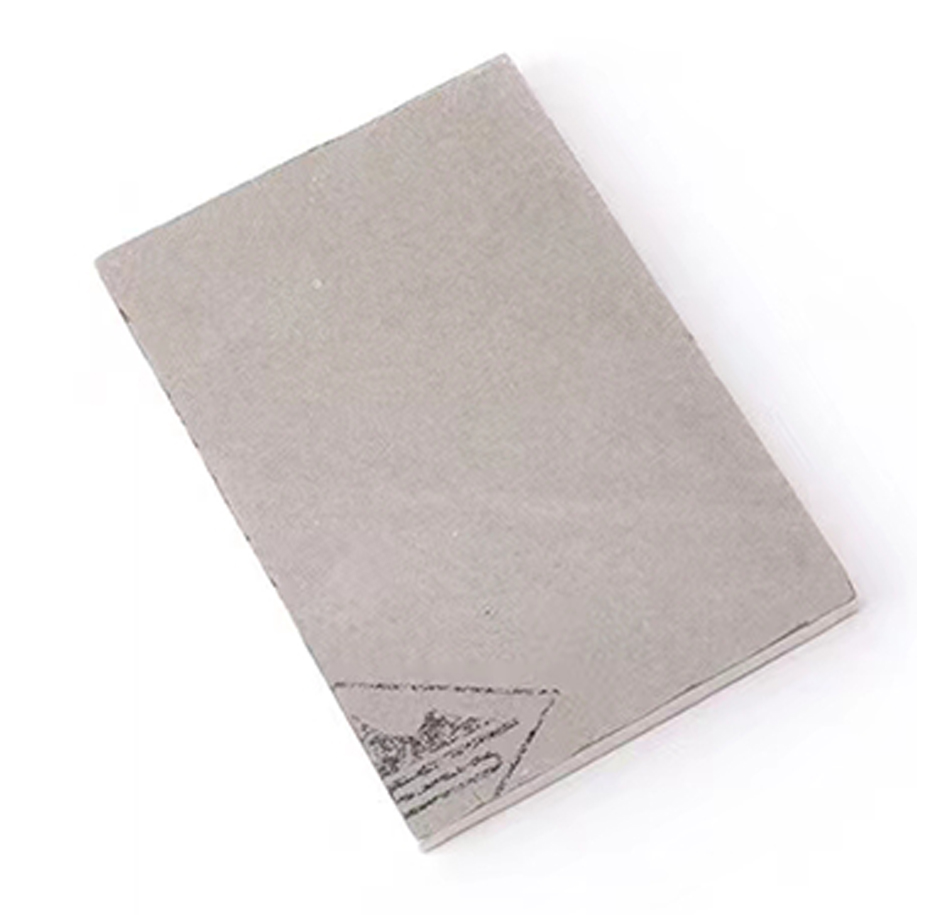

1. The component structure is different. The main components of the silicon calcium plate are natural gypsum powder, glue, white cement and glass fiber, and the main components of calcium silicate plates are Yunmu, quartz and wood fiber.

2. Different uses. Silicon calcium plates are generally used in ceiling boards, air ducts, fire doors, or barriers of various ships. Calcium silicate plates are generally used in fire ceilings, interior and outdoor walls, and high -temperature insulation environments.

3. Different classification. When classification, the silicon calcium plate is mainly divided into good, medium, and poor, while calcium silicate plates can be divided into hollow plates, patterns and panels when classification.

Introduction to the specific characteristics and use of silicon calcium board

Silicon calcium plate is actually a material specifically used in the construction industry. This board is a diversified material and is made up of many materials. Gypsum powder, so it is also called a plaster composite board. This composite board has a lot of good use performance.

The part of the silicon calcium board is more diversified, including natural gypsum powder, white cement, glue, and glass fiber. It is very excellent in the plate using these materials, which integrates the advantages of these materials. It is also widely used in the current market.

1. Introduction to the composition structure of silicon calcium board

The silicon calcium board is mainly composed of plaster powder, also called calcium silicate, and adds silicon materials, calcium materials, and enhanced fiber as production materials to it. The process is finally made into a light -quality plate of silicon calcium plate.

2. Introduction to the characteristics of silicon calcium board

Because the materials made by the silicon calcium board are all light -quality materials, and after a series of processing and production, some of the unnecessary impurities are removed, leaving the essence part, so that this composite plate is it. The quality is very lightweight.

It also has a very powerful anti -corrosion and moisture -proof effect on silicon calcium board

The material of the silicon calcium board is strong, and the multi -process processing process is adopted, so that the strength of this plate can be greatly improved, and its materials are unsplegly, fireproof, fire prevention Material, so its fire prevention performance is also very good.

It adds a lot of fibrous materials for the silicon calcium board, so that its fiber and toughness are greatly improved, so it will be more convenient when processing and production, and it is not easy to be broken.

3. Introduction to the application field of silicon calcium board

It has so many excellent characteristics, so it is often widely used in high -rise buildings, public buildings and some partition walls that need fire prevention, etc. The production of ceiling and the production of chandeliers and so on.

In short, it has a better workmanship and better performance in the silicon calcium board itself than other products of the same type. Therefore, the use of this composite board is becoming more and more.