Perforated gypsum board, a powerful sound insulation material delayed by the name!

Time: 2022-08-29 18:24:13

What is perforated drywall?

1. Definition of perforated gypsum board

Perforated gypsum board, also known as perforated gypsum sound-absorbing board, is a kind of perforation with acoustic performance formed by using high-strength characteristic substrate, according to different hole types, through high-density perforation and backing with a breathable sound-absorbing film. sound-absorbing panels.

2. Characteristics of perforated gypsum board

a. Good acoustic performance

Sound insulation and sound absorption, can absorb sound wave energy, effectively adjust the indoor reverberation time through the combination of different apertures, hole distances, perforation rates and cavities, especially the absorption of low-frequency sound waves.

b. Strong decorative

The surface of the perforated gypsum board is flat, and the joints are processed to form a seamless surface, and the surface can be directly decorated. At the same time, the pores have various forms and rich combinations, which can form a unique texture effect and have strong decorative properties.

c. Superior performance

Light weight, high strength, good toughness, waterproof and moisture-proof, anti-corrosion and moth-proof, thermal insulation, and good fire performance, fire resistance grade can reach Class A, with good fire resistance and flame retardant performance.

d. Green and environmental protection

Most of the perforated gypsum boards use natural gypsum and paper as raw materials, and absolutely do not contain asbestos, benzene, formaldehyde and other substances that are harmful to the human body. They are environmentally friendly, healthy and safe.

e. Convenient construction

The perforated gypsum board has the properties of nailing, planing, sawing and sticking. It is used for interior decoration, and the construction is very convenient, which can greatly improve the construction efficiency. Shorten the construction period and save costs.

3. Common parameters

Common parameters of perforated gypsum board are as follows:

The size specifications are usually 1200×2400mm, 1220×2440mm, 1200*2700mm, 1200×3000mm, 600×600mm, etc. At the same time, the size can be customized according to the design requirements.

The aperture size is usually 3~10mm, which is selected according to the decorative effect and sound absorption.

The thickness of the plate is usually 9~15mm, mostly 9.5mm, 12mm or 15mm.

(The above are the common parameters of most products on the market, for reference only)

4. Price range

Perforated gypsum board is mainly affected by factors such as size, thickness, perforation style, aperture size, material performance, brand, etc. The price range is 25~55 yuan/㎡. Usually sold by sheet, taking the size of 1220×2440×9.5mm as an example, the price is usually 65~90 yuan per sheet.

(The above price is only the common mid-end price in the market. The material price will fluctuate greatly according to different projects, different brands, and customization, and is for reference only.)

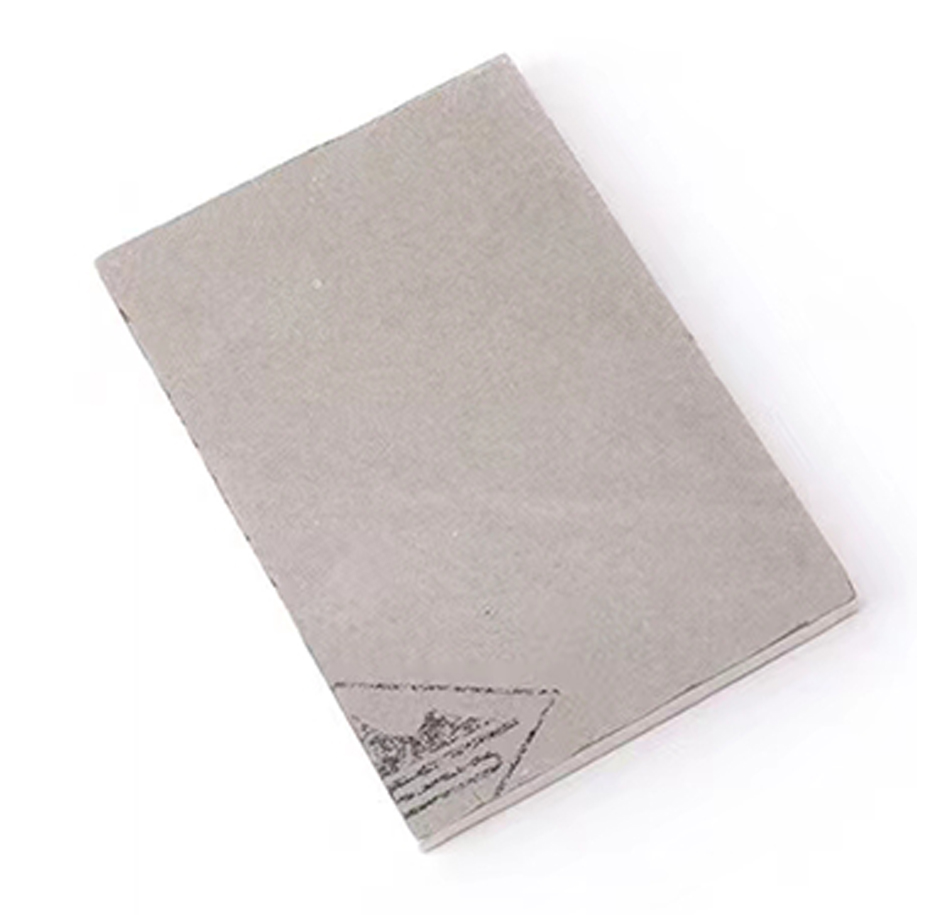

perforated plasterboard

Process principle, hole type and material comparison

1. Processing technology

Since the raw material is mainly gypsum, the processing technology of perforated gypsum board is relatively simple. Taking one of the cloth pattern perforated gypsum boards as an example, the specific process is as follows:

a. Select the mold

b. Fill in

c. Shake well, stick sound-absorbing material on the back

d. Stripping

e. to dry

f. Finished product

2. The principle of sound absorption

The perforated gypsum board has a large number of tiny connected pores, which form a "Helmholtz resonance" cavity with the gypsum board itself and the surface layer of the original building structure. Convert part of the sound energy into heat energy for sound absorption.

3. Hole type

The most common types of holes are round holes, square holes, crossed round holes and irregular holes.

3. Material comparison (with ordinary gypsum board)

a. Finishing texture

Perforated drywall: There are various types and sizes of holes.

Ordinary gypsum board: the surface is smooth and flat, without holes.

b. Performance

Perforated gypsum board: the most significant is the acoustic performance, excellent sound absorption and sound insulation. At the same time, it has the characteristics of light weight and high strength, convenient processing, thermal insulation, fireproof and moistureproof, mildew proof, and easy to dust.

Ordinary gypsum board: light weight, high strength, thin thickness, easy processing, and good performance such as sound insulation, heat insulation and fire protection.

c. Price

Perforated gypsum board: gypsum is used as the main raw material, but the process is relatively complicated, and the cost and price are relatively high. Taking the size of 1220×2440×9.5mm as an example, the average price range is 65~90 yuan/piece.

Ordinary gypsum board: using gypsum as the main raw material, the process is relatively simple, and the cost and price are relatively low. Taking the size of 1220×2440×9.5mm as an example, the average price range is 25~40 yuan/piece.

Construction technology of perforated gypsum board

The construction process of the perforated gypsum board in the indoor space with sound insulation requirements is similar to that of the ordinary gypsum board ceiling.

Construction process:

Construction preparation → elastic line positioning → installation of structural skeleton → installation of perforated gypsum board → board seam treatment → finish treatment.

1. Construction preparation

Confirm whether the pipeline reservation of water, electricity and equipment has been basically completed and meets the design requirements. Prepare construction materials and tools according to the requirements of on-site measurement and design drawings.

2. The positioning of the elastic line

According to the requirements of the design drawings, the elevation line pops up on the wall column, and the layout point control line for the boom pops up at the bottom of the floor.

3. Install the structural skeleton

Drill holes in the position of the boom, connect the boom to the floor structure with expansion bolts, and connect the main keel to the hanging bars with hanging pieces; then complete the installation and fixation of the side keel, the secondary keel and the cross-bracing keel in sequence.

4. Install perforated gypsum board

Fix the perforated gypsum board on the secondary keel and the horizontal support keel with galvanized self-tapping screws. The nail distance should be reasonable, the nail head should be embedded in the gypsum board by 0.5~1mm, and the top cap should be painted with anti-rust paint and smoothed with putty.

5. Seam processing

a. If the non-painting type perforated gypsum board is selected, the position of the board joints is usually treated with metal strip caulking.

b. If the perforated gypsum board with decorative surface needs to be painted, it is necessary to fill the board seam with caulking putty, select the joint paper tape of the appropriate width, and stick the joint paper tape on the inlay with adhesive or white latex. On the seam that has been sewn, cover the seam by a certain distance.

6. Finishing treatment

Finishing is required if perforated plasterboard other than the paint-free type is chosen. Scrape the prepared putty or finished putty in batches, generally scraping and polishing three times. After the putty is completed, the surface of the gypsum board should be painted with paint, generally with a roller brush or a sprayer.

7. Precautions

a. When the perforated gypsum board is installed and connected, the continuity of the perforation should be ensured in a crisscross manner. For the connection, do not cover the perforated position with putty. If it is covered, it should be removed as much as possible.

② When scraping putty in batches, it is necessary to pay attention to the connection and end of the putty. After each layer of putty is dry, it must be sanded with a sandpaper machine.

b. Different types of paint can be used, but the material selected should not reduce its sound quality.

8. Node structure